Bespoke Tooling

We will work with you to understand your production requirements. Then, we will design and develop the best woodworking solution for your specific needs. We can create bespoke blocks to suit any manufacturing or machining processes to increase the efficiency and quality of your products. Our UK team of expert engineers are always improving production methods and producing optimum performance tooling. You will have one of our specialist team assigned to you, following your project through from idea to completion, working directly with you to make sure you get the very best from Whitehill bespoke tooling. Alongside Whitehill's enormous selection of standard profile cutters, check out just some of our available cutter heads and cutter blocks on this website and our online catalogue.Idea & Design

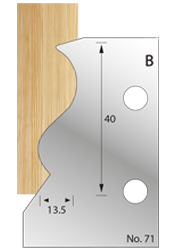

Send in an image, wood sample or drawing of what you want. Mention what machine it is for and what you want to make with it. We will give you the design options available. We will advise you on the best material to use for the job. Using lean principles, we will look to improve tool design to make the process more efficient, including zero set tools, tool splitting solutions, quick tool changing, single-pass machining and adjustable tools for varying material sizes.

Once we know the criteria and your unique requirements, our specialist design team will come up with solutions. Using the latest 3D technical CAD software gives us flexibility in design, aiding us in delivering the ideal solution to you. You will be sent them directly from our team and given a chance to work with us on your bespoke project.

Manufacture

Once the designed has been approved, your 3D model gets programmed and then machined. Our raw materials used have full traceability, and we have the latest advances in machining practises.

The required cutter blocks are then manufactured using the latest industry 4.0 production methods. By using our advanced mill-turn machine, we produce it in one process. It goes from raw material to a finished component in just one pass.

We use in-process measurement to ensure quality at all times. Each Tool goes through rigorous testing, inspection and quality checks providing our customers with the assurance that the products received are the best quality before the made in Britain logo is added.

Then, the tools are securely packaged, despatched and delivered out to you. Depending on the complexity of the tooling, we can offer assistance during installation.

Service & Support

At Whitehill Tools, we are dedicated to providing comprehensive support to our customers beyond just supplying high-quality products. Our team is committed to assisting with aftercare and installation.

We will help set you up, providing you with advice and all the tools, ensuring longevity and precision of your production. If you need help with aftercare, installation, or any aspect of your production process, do not hesitate to reach out to us. Our team is here to support you and ensure that your production experiences are successful. Contact us today to learn more about how we can assist you with your specific needs.