Product Showcase - 15 & 20 Degree Shallow Bevel Kitchen & Cabinet Door Set

20 February 2025

Enhance Your Workshop Productivity with Whitehill's Tooling Solutions

Having the right manufacturing tools can really make a difference for woodworking businesses, especially those that create kitchen and cabinet doors. It’s important to have an efficient production process to ensure good quality, meet deadlines, and stay competitive.

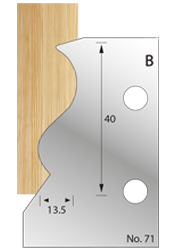

To help with this, our engineers have developed four tools designed specifically for spindle moulders and shapers. These tools include two blocks for adding grooves to wood and two more for scribing and tenoning in one step. This makes it much easier to create shallow bevel doors.

CLICK HERE TO SEE IT IN ACTION!

Key Features of Our Tool Set

Zero Set Tooling: The constant height and diameter design ensures that once the spindle height and fence are set, the next set of tooling can be placed on the spindle without requiring further adjustments. This feature saves time and minimizes the risk of errors in the production process.

Available Bore Sizes: Tooling is available in 30mm and 1 ¼ inch bore sizes, with additional options available upon request to cater to various workshop needs.

Door Thickness Range: The tools accommodate a wide range of door thicknesses from 22mm to 33mm, making them versatile for various types of door production.

Block Features: Our blocks are designed to be durable, reliable, and suitable for a variety of woodworking applications. They come with replaceable tungsten carbide knives, which can be sourced from Whitehill.

Blade Positioning: The unique design ensures that the blades can only be installed in one position, guaranteeing reliable and accurate alignment every time they are replaced.

Material Compatibility: Our cutters are suitable for various wood types, including MDF, timber, hardwoods, and softwoods.

Customisation Options for Your Workshop

The Whitehill tool set is highly customizable, allowing shops to tailor the solutions to their specific needs. We work closely with customers to develop customized tooling for various machines, including:

CNC Machines: We design and manufacture custom tooling for CNC machines to meet specific workshop requirements.

Moulder and Tenoner Setups: Our tooling is compatible with various moulder and tenoner configurations, ensuring seamless integration with existing equipment.

Vertonghen Kitchen Cell Machines: We have expertise in designing customized tooling for Vertonghen Kitchen Cell machines to enhance their functionality.

Bespoke Fixed Tooling: For one-off or small production runs, we can create customized fixed tooling to meet specific workshop needs.

Get in Touch with Whitehill Tools

If you're interested in learning more about our tooling solutions or would like to explore customization options for your workshop, please don't hesitate to contact us at sales@whitehill-tools.com. We're committed to helping you optimize your production processes and improve your overall efficiency.

Comments

There are currently no comments, be the first to comment.